Explore the Range of Chemical-Resistant Gloves Available in the UK

What Varieties of Chemical-Resistant Gloves Can You Find in the UK Market?

When conducting a comparative analysis of chemical-resistant gloves against standard disposable options in the UK, it becomes evident that a broad array of chemical-resistant gloves is available, specifically designed to protect workers from hazardous substances. The most prevalent types include nitrile and latex gloves, both of which comply with stringent safety regulations established in the UK. These gloves provide exceptional barrier protection, proving essential in numerous sectors, including manufacturing, healthcare, and laboratories. Rigorous testing and adherence to British safety standards ensure these gloves can withstand exposure to a diverse range of chemicals, effectively shielding workers while maintaining health compliance.

UK manufacturers employ a variety of key materials to enhance the durability and performance of chemical-resistant gloves. Below is an extensive compilation of commonly utilised materials:

- Nitrile: Renowned for its exceptional resistance to oils, solvents, and a wide selection of chemicals.

- Latex: Offers excellent elasticity and comfort, making it ideal for precision tasks.

- Neoprene: Combines flexibility with chemical resistance, making it suitable for various applications.

- Vinyl: Commonly used for low-risk tasks, though less effective against chemicals compared to nitrile and latex.

- Butyl rubber: Known for its high resistance to gases and vapours, frequently used in specialised applications.

- Polyvinyl chloride (PVC): Recognised for its durability and corrosion resistance, often employed in industrial environments.

These materials highlight the UK’s unwavering commitment to workplace safety, ensuring that employees are thoroughly protected from hazards encountered in their daily tasks.

What Are the Common Types of Standard Disposable Gloves in Use Across the UK?

In the UK, standard disposable gloves are primarily made from polyethylene or vinyl, commonly utilised for general tasks across sectors such as healthcare and food services. While these gloves provide a basic level of protection against non-hazardous materials, their limited chemical resistance significantly diminishes their effectiveness in environments where chemical exposure poses a notable risk.

In healthcare settings, standard disposable gloves are frequently employed during routine procedures, including examinations and food handling. However, their thin construction makes them unsuitable for tasks involving hazardous chemicals. This lack of chemical resistance can result in considerable risks, particularly in laboratories or industrial environments where chemical spills represent a threat.

Due to their limited durability and protective capabilities, standard disposable gloves are often regarded as a temporary solution, leading to increased waste and the necessity for frequent replacements. Consequently, while they help uphold hygiene standards, they do not meet the safety requirements for more hazardous applications.

What Are the Principal Differences Among Glove Materials Available in the UK?

In the UK, variations in glove materials can significantly influence their protective performance. Chemical-resistant gloves are meticulously crafted with specific polymers that enhance protection against acids and solvents. For instance, nitrile gloves are engineered to withstand exposure to various chemicals, including oils and hazardous substances, making them a preferred choice in numerous industrial settings.

In contrast, standard disposable gloves, typically made from vinyl or polyethylene, degrade quickly when exposed to chemicals. This deterioration not only compromises the gloves’ structural integrity but can also lead to skin exposure, increasing the risk of chemical burns or allergic reactions among workers. The superior barrier properties of chemical-resistant gloves arise from their thickness and the quality of materials used, which are particularly crucial in British industrial sectors with strict safety standards.

Ultimately, selecting the appropriate glove material can profoundly affect worker safety. For UK industries managing corrosive or toxic substances, opting for chemical-resistant gloves over standard disposables is essential to ensure compliance with health and safety regulations.

How Do Chemical-Resistant Gloves Ensure Worker Safety in the UK?

What Factors Affect the Effectiveness of Chemical-Resistant Gloves in UK Work Environments?

Several critical factors significantly influence the protective performance of chemical-resistant gloves in UK settings. Among these, glove thickness is paramount, as thicker gloves generally provide a more robust barrier against corrosive substances. In British factories, where exposure to hazardous materials is commonplace, this thickness effectively prevents chemicals from penetrating the glove and making contact with the skin.

Moreover, the materials used in glove construction, such as nitrile or neoprene, can enhance protection against specific types of chemicals. Coating materials also improve effectiveness; gloves with additional coatings can enhance grip and dexterity, which are essential for delicate tasks that require precision. Compliance with UK health and safety regulations is another factor affecting glove efficacy, as these guidelines mandate rigorous testing for chemical resistance.

Education and training play a crucial role in maximising the effectiveness of these gloves in the workplace. Workers must receive comprehensive training on the proper use and limitations of chemical-resistant gloves, ensuring they understand when to replace them and how to maintain their protective qualities. This training is vital in preventing accidents and cultivating a safe working environment.

What Limitations Do Standard Disposable Gloves Present for Workers in the UK?

Standard disposable gloves impose numerous limitations on UK workers, especially in environments where there is a risk of chemical exposure. These gloves are primarily designed for low-risk tasks, such as food preparation or basic medical examinations, and are not intended to provide protection against hazardous chemicals. Their thin construction makes them vulnerable to tearing or puncturing, significantly diminishing their effectiveness against corrosive substances.

In UK laboratories, for example, prolonged exposure to chemicals can lead to deterioration of glove material, resulting in skin contact with harmful substances. This scenario not only poses significant health risks to workers but also increases the likelihood of non-compliance with British workplace safety standards, potentially leading to penalties for employers.

The shortcomings of standard disposables can also raise operational costs. Frequent replacements due to wear and tear can escalate expenses over time, particularly for organisations that routinely handle chemicals. Accordingly, while standard disposables may be adequate for low-risk tasks, they fall short for more hazardous applications, underscoring the importance of selecting gloves based on specific task requirements.

What Are the Practical Applications of Chemical-Resistant Gloves in British Industries?

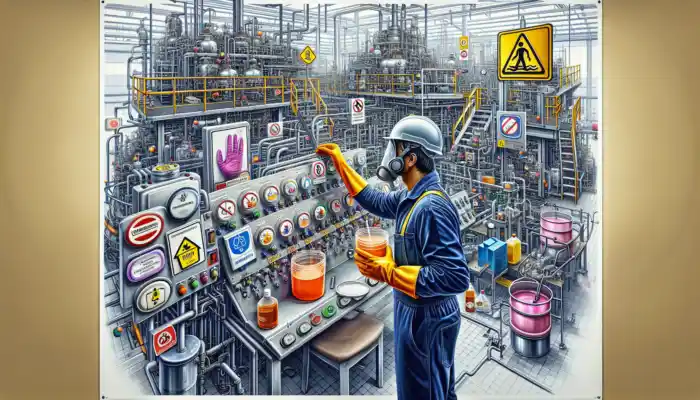

The practical applications of chemical-resistant gloves within British industries illustrate their vital role in preventing accidents. In the manufacturing sector, for instance, workers handling chemicals such as solvents and acids rely on nitrile gloves to protect their skin. Case studies from UK factories demonstrate that the use of these gloves significantly reduces incidents of chemical burns and related injuries.

In the pharmaceutical industry, where strict hygiene and safety standards are paramount, chemical-resistant gloves are often mandated to safeguard personnel from potentially hazardous substances. The implementation of stringent safety protocols, including proper glove usage, has led to a noticeable decline in workplace injuries, highlighting the effectiveness of these measures in real-world scenarios.

Conversely, reliance on standard disposable gloves in these environments has resulted in numerous safety violations. Numerous documented incidents illustrate that using inferior gloves has led to accidents due to inadequate protection against spills and splashes. These examples emphasise the necessity for industries across the UK to prioritise the use of chemical-resistant gloves, ensuring worker safety while maintaining compliance with health and safety regulations.

What Expert Insights Are Available Regarding the Comparison Between Chemical-Resistant Gloves and Standard Disposable Options?

What Expert Evaluations Exist on UK-Specific Glove Designs?

Experts in personal protective equipment (PPE) consistently advocate for the adoption of chemical-resistant gloves to enhance safety in UK workplaces. British engineers and safety professionals underscore the need for designs tailored to various industries, ensuring that gloves not only meet safety standards but also remain practical for daily use.

The design of chemical-resistant gloves typically includes features such as reinforced seams and textured surfaces for improved grip, particularly beneficial in high-stakes environments where precision is crucial. Real-world examples from UK case studies indicate that companies implementing these gloves have reported a significant decrease in workplace accidents, attributing this success to the superior design and materials of these protective gloves.

Furthermore, experts stress the importance of selecting gloves that fit correctly to ensure a snug fit. Ill-fitting gloves can compromise dexterity and increase the likelihood of accidents, making proper selection critical. The emphasis on UK-specific designs guarantees compliance with local regulations, further enhancing workplace safety and adherence.

What Essential Features Are Endorsed by Experts for Use in the UK?

When examining the features endorsed by experts for chemical-resistant gloves compared to standard disposables, several key factors emerge. Safety specialists in the UK typically recommend gloves with enhanced chemical resistance, such as those made from nitrile or neoprene, which provide superior protection against a diverse range of hazardous substances. These gloves often incorporate traditional design elements, such as ergonomic features for improved comfort and extended cuffs for increased wrist protection.

Conversely, standard disposable gloves lack these essential features, as they are primarily designed for short-term use in low-risk environments. The absence of robust materials and protective characteristics renders these gloves unsuitable for tasks where there is potential for chemical exposure.

Expert insights also highlight the critical importance of testing and certification for chemical-resistant gloves. In the UK, stringent regulations require that these gloves undergo comprehensive testing to ensure they meet safety standards. This level of scrutiny is generally not applied to standard disposables, raising concerns regarding their reliability in hazardous settings.

Ultimately, experts’ preference for chemical-resistant gloves is driven by their superior protective performance and adherence to UK regulations, underscoring the necessity for industries to invest in high-quality PPE to safeguard their workforce.

What Steps Should UK Professionals Consider for Effective Implementation?

For UK professionals aiming to integrate chemical-resistant gloves into workplace safety protocols, several actionable steps are worth consideration. Firstly, conducting a thorough risk assessment is essential to identify tasks that require enhanced chemical protection. This assessment should evaluate the types of chemicals present, the duration of exposure, and the potential for spills or splashes.

Next, selecting the appropriate type of chemical-resistant glove is critical. UK professionals should consider factors such as material type, thickness, and fit to ensure that the gloves align with the specific needs of their tasks. Additionally, training employees on the proper use and maintenance of these gloves can further strengthen safety and compliance, ensuring workers understand when to replace them and how to inspect them for damage.

Establishing a glove management system can also streamline the selection and distribution process. This system should include guidelines for glove usage, maintenance, and disposal to foster a culture of safety within the organisation. By adhering to these actionable steps, UK professionals can ensure their workplaces are better equipped to safely manage hazardous materials.

How Do UK Regulations Shape Glove Selection?

How Do UK Laws Influence the Choice of Gloves?

UK laws significantly impact glove selection, particularly regarding chemical-resistant gloves. British regulations, including the Personal Protective Equipment at Work Regulations, mandate that employers provide suitable PPE that meets safety standards. This includes rigorous testing for chemical-resistant gloves to ensure they meet higher safety requirements than disposable options.

The regulations also stipulate that gloves must be assessed for suitability based on the types of chemical exposures workers might encounter. As a result, employers must consider not only the gloves’ material properties but also their performance in real-world applications. Complying with these laws not only protects workers but also mitigates potential legal liabilities for employers.

Moreover, UK regulations require manufacturers to provide comprehensive information regarding performance capabilities, such as resistance to specific chemicals and any limitations. This transparency enables businesses to make informed decisions when selecting PPE, aligning with industry standards, and promoting a culture of safety.

What Regulatory Scrutiny Do Standard Disposable Gloves Face in the UK?

Standard disposable gloves are increasingly scrutinised under UK regulations due to their limitations in protecting workers from hazardous materials. Many of these gloves fail to meet the stringent certification requirements for high-risk environments, such as the pharmaceutical and chemical processing sectors. This inadequacy raises significant concerns, particularly in industries where chemical exposure is prevalent and can lead to severe health implications.

The lack of durability and protective features in standard disposable gloves renders them unsuitable for handling dangerous materials, amplifying the risk of accidents and injuries. Regulators in the UK are becoming more stringent in enforcing compliance, and businesses that depend on these gloves may face penalties or legal repercussions if they do not adhere to safety standards.

As employers become increasingly aware of the risks associated with inadequate PPE, there has been a noticeable trend towards investing in chemical-resistant alternatives. This shift demonstrates a growing recognition of the importance of worker safety and compliance with UK regulations, ultimately leading to a safer working environment.

What Are the Evolving Standards Within the UK Glove Market?

The UK glove market is continually evolving, particularly in response to updates in safety regulations and advancements in glove technology. Recent updates to UK guidelines have emphasised the necessity for gloves with enhanced chemical resistance, clearly distinguishing them from standard gloves. Evolving standards ensure that protective gear meets the highest levels of safety and effectiveness.

Manufacturers are innovating to produce gloves that not only meet but also exceed regulatory requirements, incorporating advanced materials and design features to enhance usability and protection. This shift has led to a broader selection of high-quality chemical-resistant gloves available in the UK market, catering to specific industry needs.

As the demand for safer working environments grows, businesses are encouraged to conduct regular reviews of their PPE policies and practices to align with evolving standards. By staying informed and adapting to these changes, companies can ensure compliance while fostering a safety culture that prioritises employee well-being.

How Do UK Glove Regulations Compare with International Standards?

In the UK, glove regulations typically exceed international standards by requiring rigorous testing to guarantee enhanced chemical and physical resistance. This commitment to safety improves workplace protection, significantly influencing import decisions and raising the quality threshold for protective gear across British industries.

UK regulations mandate that chemical-resistant gloves undergo comprehensive assessments to evaluate their effectiveness against specific chemicals, typically more stringent than those in other countries. This rigorous approach instils confidence in the safety and reliability of the gloves available in the UK market.

Moreover, the UK’s emphasis on continuous improvement in glove technology stimulates innovation, leading to products that offer superior protection compared to international counterparts. As other nations strive to align with UK standards, the UK remains at the forefront of glove safety and efficacy, setting a high benchmark for protective equipment globally.

What Advantages Do Chemical-Resistant Gloves Offer to UK Industries?

What Primary Advantages Are Noted in the UK Manufacturing Sector?

In the UK manufacturing sector, the use of chemical-resistant gloves provides significant benefits, particularly in reducing injury rates associated with chemical exposure. These gloves are meticulously designed to deliver a robust barrier against harmful substances, significantly lowering the likelihood of accidents and skin contact with hazardous materials.

The durability of chemical-resistant gloves further enhances their effectiveness. Unlike standard disposables that deteriorate rapidly, these gloves maintain their structural integrity over extended use, thereby ensuring ongoing protection for employees. This longevity not only supports safety but also reduces the frequency of replacements, ultimately leading to cost savings for businesses.

Moreover, implementing chemical-resistant gloves fosters a culture of safety within organisations. When employees feel protected, their productivity often increases, as they know their well-being is prioritised. This focus on safety can improve morale and reduce turnover, providing additional benefits to the manufacturing sector.

What Are the Economic Implications for UK Businesses?

The economic implications of utilising chemical-resistant gloves in UK businesses are considerable. Although the initial investment in high-quality gloves may exceed that of standard disposable options, the long-term savings are substantial. By investing in durable gloves, organisations can significantly reduce costs associated with frequent glove replacements and minimise downtime due to accidents or injuries.

In chemical-intensive workplaces, the financial repercussions of workplace accidents can be severe, encompassing legal fees and regulatory fines. By prioritising the use of chemical-resistant gloves, companies can mitigate these risks, leading to a more sustainable financial model.

Additionally, the enhanced protection provided by chemical-resistant gloves can diminish occupational health claims over time, further contributing to cost savings. By preventing injuries and ensuring compliance with health and safety regulations, businesses can protect their financial interests while safeguarding their employees.

What Long-Term Health Benefits Are Associated with Using Chemical-Resistant Gloves for UK Workers?

The long-term health benefits of chemical-resistant gloves for UK workers are significant, particularly in high-risk industries. These gloves provide superior protection against hazardous substances, dramatically decreasing the chances of chemical burns, allergic reactions, and other skin-related health issues.

By ensuring that employees are shielded from harmful exposures, businesses can cultivate a healthier workforce, resulting in lower healthcare costs and reduced absenteeism. Workers equipped with effective PPE are less likely to face long-term health complications, thereby enhancing their overall quality of life and job satisfaction.

Furthermore, the use of chemical-resistant gloves aligns with broader public health initiatives aimed at improving workplace safety standards. By investing in suitable protective equipment, organisations foster a culture of health and safety that benefits not only individual workers but society as a whole.

What Research-Backed Benefits Exist for Chemical-Resistant Gloves Compared to Standard Disposables?

What Real-World Studies Highlight Benefits in the UK?

Research conducted within the UK has underscored the tangible benefits of employing chemical-resistant gloves over standard disposables. For example, studies in manufacturing and laboratory environments have demonstrated that workers using chemical-resistant gloves experience significantly lower rates of chemical-exposure incidents in contrast to their counterparts using standard disposable gloves.

In one notable instance, a UK-based chemical manufacturing plant implemented a policy mandating the use of chemical-resistant gloves for all employees engaged in handling hazardous materials. Within six months, the facility reported a 40% decrease in chemical-related injuries, showcasing the effectiveness of these gloves in preventing workplace accidents.

This data highlights the critical importance of selecting appropriate PPE and investing in higher-quality gloves, which can significantly improve worker safety. The findings from these studies serve as a compelling call to action for businesses across the UK to prioritise the adoption of chemical-resistant gloves, particularly in environments with a high risk of chemical exposure.

What Expert Assessments Exist Regarding Durability in the UK Context?

Expert evaluations of glove durability in the UK context consistently favour chemical-resistant options over standard disposables. Laboratory tests conducted under controlled conditions have demonstrated the superior performance of chemical-resistant gloves when exposed to various hazardous substances.

Experts have found that, in demanding environments, chemical-resistant gloves maintain their structural integrity significantly longer than standard disposables, often displaying minimal signs of wear and degradation even after limited chemical exposure. This durability is particularly crucial in sectors such as pharmaceuticals and manufacturing, where prolonged contact with dangerous materials is routine.

The robustness of chemical-resistant gloves not only enhances worker safety but also results in substantial cost savings for businesses. By reducing the necessity for frequent replacements, organisations can allocate resources more effectively while ensuring their employees remain protected.

What Trusted Strategies Should Be Adopted for Effective Implementation in the UK?

For UK businesses aiming to incorporate chemical-resistant gloves, adopting trusted strategies can yield better outcomes than relying solely on standard disposables. Firstly, conducting comprehensive training programs for employees on the correct use and limitations of chemical-resistant gloves is crucial. Workers should understand the specific tasks for which these gloves are appropriate and how to utilise them effectively. Establishing a glove selection policy can ensure that the appropriate types of gloves are used for various applications. This approach should factor in elements such as chemical exposure risks, glove material properties, and specific job requirements to promote a tailored PPE strategy.

Regularly reviewing and updating glove-use policies in accordance with the latest industry standards and regulations will further enhance workplace safety. By committing to these evidence-based strategies, UK organisations can significantly bolster their protective measures against chemical exposure, ultimately cultivating safer work environments for their employees.

What Are the Guidelines for Glove Usage in UK Workplaces?

Why Are Chemical-Resistant Gloves the Preferred Choice in UK Laboratories?

Chemical-resistant gloves are the preferred option in UK laboratories primarily due to their effectiveness in protecting against hazardous substances, including acids and solvents. The nature of laboratory work frequently involves handling corrosive chemicals, making it essential for scientists and technicians to utilise gloves that provide a robust barrier against potential spills and splashes.

Moreover, chemical-resistant gloves offer the necessary dexterity for precise tasks, such as pipetting or handling delicate instruments. Many UK laboratories favour nitrile gloves for their balance of flexibility and chemical resistance, enabling workers to perform intricate tasks safely.

Additionally, selecting chemical-resistant gloves aligns with the stringent safety standards upheld in UK laboratories. Adhering to these standards is vital to ensure that laboratory personnel are adequately protected while conducting experiments, further emphasising the necessity of employing high-quality PPE.

What Role Do Standard Disposable Gloves Play in Everyday UK Tasks?

While standard disposable gloves serve their purpose in everyday tasks across UK workplaces, their limitations become apparent in environments heavy with chemicals. These gloves are typically used for general tasks such as food handling or basic medical examinations, where the risk of chemical exposure is minimal. However, in settings like laboratories or manufacturing plants, their inadequate protective features raise significant concerns.

Standard disposables can tear or puncture easily, undermining their ability to prevent skin contact with hazardous materials. In workplaces with a heightened risk of chemical exposure, relying solely on these gloves can lead to dangerous situations, including chemical burns and skin irritations.

Employers must evaluate the appropriateness of standard disposables for specific tasks and consider transitioning to chemical-resistant alternatives whenever there is a potential for chemical exposure. This proactive approach to safety will help mitigate risks and enhance the overall safety culture within the organisation.

What Training Is Necessary for UK Staff Regarding Glove Usage?

Training requirements for UK staff regarding glove usage are crucial for ensuring optimal safety and compliance with health regulations. Employers must provide thorough training on the proper fitting, usage, and maintenance of both chemical-resistant and standard disposable gloves. This training should emphasise the importance of selecting the correct gloves for specific tasks, particularly in environments where chemical exposure poses a risk.

Workers should be trained to inspect gloves for signs of damage or wear before use and to adhere to the appropriate disposal procedures. Understanding the limitations of standard disposables is also essential, as is recognising when to switch to more robust chemical-resistant options.

Regular refresher training sessions can reinforce best practices and ensure that employees remain informed about the latest safety protocols and regulations. By prioritising glove training, UK businesses can enhance workplace safety and foster a culture of health and protection throughout the organisation.

What Sustainable Glove Options Are Available in UK Workplaces?

In the United Kingdom, eco-friendly glove alternatives are gaining traction in workplaces, aligning with broader sustainability initiatives aimed at reducing environmental harm. These sustainable options deliver effective protection for a range of tasks while promoting greener practices in laboratories and offices without compromising safety or durability.

Manufacturers are now producing biodegradable gloves crafted from renewable materials, providing an environmentally responsible alternative to traditional disposable options. These gloves maintain the necessary protective qualities, making them suitable for low-risk tasks while reducing waste.

Adopting sustainable glove options allows UK businesses to demonstrate their commitment to environmental responsibility, enhancing their reputation and appealing to consumers who value eco-conscious practices. By incorporating these gloves into workplace protocols, organisations can significantly contribute to sustainability while ensuring employee safety and compliance with health and safety regulations.

Why Opt for Chemical-Resistant Gloves Over Standard Disposable Options in the UK?

What Makes Chemical-Resistant Gloves Essential for Safety in the UK?

Chemical-resistant gloves are vital for safety in the UK, particularly in industries such as construction and manufacturing, where exposure to solvents and hazardous substances is more prevalent. These gloves are specifically designed to endure prolonged contact with corrosive chemicals, protecting workers from potentially life-threatening incidents arising from skin exposure.

In contrast, standard disposable gloves do not provide the same level of protection. Their thin material and lack of chemical resistance make them unsuitable for tasks involving hazardous materials, thereby increasing the risk of accidents and injuries. Employing chemical-resistant gloves significantly reduces these risks, offering reassurance for both employers and employees.

By prioritising the use of chemical-resistant gloves in high-risk environments, businesses can ensure compliance with health and safety regulations while fostering a culture of safety that prioritises worker well-being. This commitment to safety ultimately enhances productivity and morale throughout the workforce.

What Are the Cost Versus Value Considerations for UK Applications?

When evaluating the cost-to-value ratio of chemical-resistant gloves in UK applications, it is clear that investing in these gloves yields long-term savings. Though the initial cost of chemical-resistant gloves may be greater than that of standard disposable options, their durability and protective features present substantial long-term financial benefits.

Organisations using chemical-resistant gloves experience fewer workplace accidents, resulting in decreased expenses related to medical claims, legal fees, and operational disruptions. Furthermore, the longevity of these gloves means they require fewer replacements, allowing businesses to allocate resources more effectively.

Conversely, standard disposables generate more waste and necessitate frequent replacements, ultimately driving up overall costs. By opting for chemical-resistant gloves, UK businesses can achieve a balance between initial investment and long-term value, ensuring adequate protection for their workforce while maintaining financial sustainability.

What Future Trends Are Emerging in UK Glove Preferences?

Emerging trends in the UK increasingly favour chemical-resistant gloves, driven by a growing awareness of safety and sustainability. As industries evolve, there is a notable shift towards adopting higher-quality PPE that meets stringent safety standards and addresses environmental concerns.

The demand for chemical-resistant gloves is expected to rise as businesses become increasingly cognisant of the importance of protecting their workers from hazardous exposures. This trend aligns with broader public health initiatives aimed at enhancing workplace safety and minimising the environmental impact of disposable PPE.

Moreover, advancements in glove technology are facilitating innovative designs that improve both safety and usability. As manufacturers continue to develop more effective and eco-friendly options, the UK market for chemical-resistant gloves is likely to expand, underscoring a commitment to worker safety and sustainability.

What Are the Essential Maintenance and Disposal Guidelines for Gloves in the UK?

How Should Gloves Be Properly Maintained in UK Work Environments?

Proper glove maintenance in UK environments is crucial for extending their lifespan and ensuring optimal protection. Regular inspections, in accordance with established guidelines, are essential for identifying signs of wear or damage. For chemical-resistant gloves, this entails checking for punctures, tears, or degradation that could compromise their structural integrity.

Employers should implement a routine glove maintenance schedule that includes cleaning protocols to eliminate contaminants. This is particularly important for reusable gloves, which may require thorough cleaning after each use to maintain their protective features. Furthermore, storing gloves in a cool, dry area, away from direct sunlight, helps to preserve their materials and prevent premature deterioration.

Training employees on the importance of glove maintenance and the correct procedures for inspecting and caring for their PPE will foster a culture of workplace safety. By prioritising maintenance, organisations can enhance the long-term safety and effectiveness of their protective gloves.

What Are the Compliant Disposal Methods for Gloves Under UK Regulations?

Disposal methods for contaminated gloves in the UK are governed by specific waste regulations that require careful handling to minimise environmental impact. Chemical-resistant gloves contaminated with hazardous substances must be disposed of in accordance with strict guidelines to prevent soil and water contamination.

Employers should establish a clear disposal protocol that includes designated containers for hazardous waste and ensures employees are aware of the correct procedures for disposing of contaminated gloves. Regular training on these protocols can help prevent violations of UK waste regulations, safeguarding both the environment and public health.

Moreover, exploring recycling options for chemical-resistant gloves can contribute to sustainability initiatives within organisations. Many manufacturers now offer recycling programmes for used gloves, enabling businesses to reduce their environmental footprint while promoting responsible disposal.

What Comparisons of Longevity Exist in British Usage?

In British workplaces, there is a noticeable difference in longevity between chemical-resistant gloves and standard disposables. Chemical-resistant gloves are specifically engineered to withstand prolonged exposure to a variety of hazardous substances and often last significantly longer than their disposable counterparts. This durability is particularly beneficial in environments where chemicals are extensively utilised, reducing the need for frequent replacements.

In contrast, standard disposable gloves tend to degrade rapidly when exposed to chemicals, leading to a shorter lifespan and increased waste. This not only affects operational costs but also raises environmental concerns associated with excessive glove disposal.

By choosing chemical-resistant gloves, UK businesses can adopt a more sustainable approach to PPE, minimising waste and lowering overall costs. The longevity of these gloves reflects a commitment to both workplace safety and environmental responsibility.

What Are the Regulatory Requirements Surrounding Glove Maintenance in the UK?

In the UK, the Health and Safety Executive mandates regular inspections and proper maintenance of protective gloves to ensure compliance with safety standards. Employers are required to establish maintenance protocols for their PPE, emphasising the significance of testing chemical-resistant gloves for integrity and performance.

This includes conducting routine inspections to detect signs of wear or damage and ensuring gloves are cleaned and stored correctly. Standard gloves also necessitate basic maintenance to reduce contamination risks, although they typically receive less scrutiny than chemical-resistant options.

Additionally, organisations must maintain comprehensive records of glove maintenance and inspections to demonstrate compliance with UK regulations. By adhering to these regulatory requirements, businesses can enhance workplace safety while fostering a culture of health and protection among their employees.

What Is the Environmental Impact of Glove Use in the UK?

The environmental impact of glove use in the UK is significant, especially regarding waste generated. Chemical-resistant options, designed for extended use, help mitigate this issue by reducing the frequency of replacements and overall waste volume. By investing in durable, high-quality gloves, UK businesses can align their operations with sustainability goals, minimising their environmental footprint while ensuring worker safety. Many manufacturers are also exploring eco-friendly materials for glove production, further reducing their environmental impact.

Promoting responsible glove use and disposal practices can lead to a more sustainable approach across industries. Encouraging recycling programmes and the adoption of biodegradable gloves can foster a commitment to environmental responsibility while maintaining workplace safety standards.

Frequently Asked Questions About Gloves

What Are Chemical-Resistant Gloves?

Chemical-resistant gloves are specialised protective gear made from materials that provide a barrier against hazardous substances, ensuring worker safety in environments where chemical exposure poses a risk.

Why Are Chemical-Resistant Gloves Preferred Over Standard Disposable Gloves?

Chemical-resistant gloves offer superior protection against chemicals, while standard disposables lack the durability and chemical resistance necessary to withstand exposure, making them unsuitable for high-risk tasks.

What Materials Are Commonly Used in Chemical-Resistant Gloves?

Common materials include nitrile, latex, neoprene, and butyl rubber, each providing varying levels of protection against different chemicals and hazards.

How Do UK Regulations Impact Glove Selection?

UK regulations mandate specific testing and performance standards for chemical-resistant gloves, ensuring they meet higher safety requirements than standard disposable options.

Which Industries Benefit the Most from Chemical-Resistant Gloves?

Industries such as manufacturing, pharmaceuticals, and laboratories significantly benefit from chemical-resistant gloves due to their exposure to hazardous substances.

How Can Businesses Reduce Glove Waste?

Businesses can minimise glove waste by investing in durable, reusable, chemical-resistant gloves, promoting responsible disposal practices, and exploring recycling options for used gloves.

What Training Is Required for Staff Using Chemical-Resistant Gloves?

Staff should receive training in proper glove selection, usage, inspection, and maintenance, as well as understanding the limitations of standard disposable gloves.

Are There Sustainable Options Available for Gloves in the UK?

Yes, many manufacturers now offer biodegradable and eco-friendly glove alternatives that provide effective protection while minimising environmental harm.

How Do Chemical-Resistant Gloves Enhance Workplace Safety?

By providing a robust barrier against hazardous substances, chemical-resistant gloves significantly reduce the risk of injuries and chemical exposure, fostering a safer environment for workers.

What Are the Cost Implications of Using Chemical-Resistant Gloves?

While chemical-resistant gloves may incur a higher upfront cost, their durability and effectiveness lead to long-term savings by reducing injury-related expenses and the need for frequent glove replacements.

Connect with us on Facebook!

The Article: Chemical-Resistant Gloves vs Standard Disposables first published on https://www.gloveclub.co.uk

The Article Chemical-Resistant Gloves: A Comparison with Standard Disposables Was Found On https://limitsofstrategy.com